"Berang" (berang)

"Berang" (berang)

04/26/2016 at 19:58 ē Filed to: engines, valves

10

10

15

15

"Berang" (berang)

"Berang" (berang)

04/26/2016 at 19:58 ē Filed to: engines, valves |  10 10

|  15 15 |

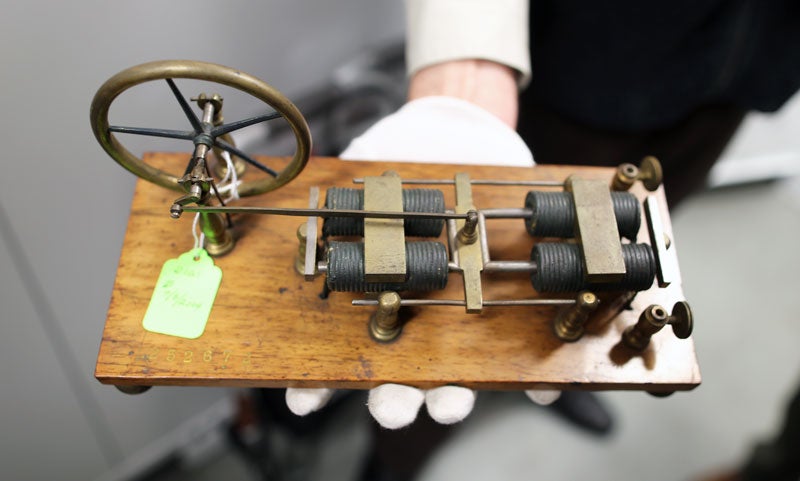

The majority of automobiles are powered by something that is essentially a variant of Georgian era engineering. The conventional 4-stroke cycle, reciprocating, internal combustion engine, is in basic principals not much different than steam engines that were being built in the 1790s.

The reciprocating steam engine works on the same basic principal as a modern automobile engine. A force contained in a cylinder, pushes on a piston, which pushes on a connecting rod, which pushes on a crank, turning it. Momentum then keeps everything spinning and flapping wildly around until force pushes on the piston again. In the steam engine, this force was provided by steam, which was generated in a boiler, heated by fuel which was burned outside of the engine itself. In an internal combustion engine, the force is supplied by fuel which is burned inside of the cylinder. No insulting of intelligence intended, just setting up the next paragraph.

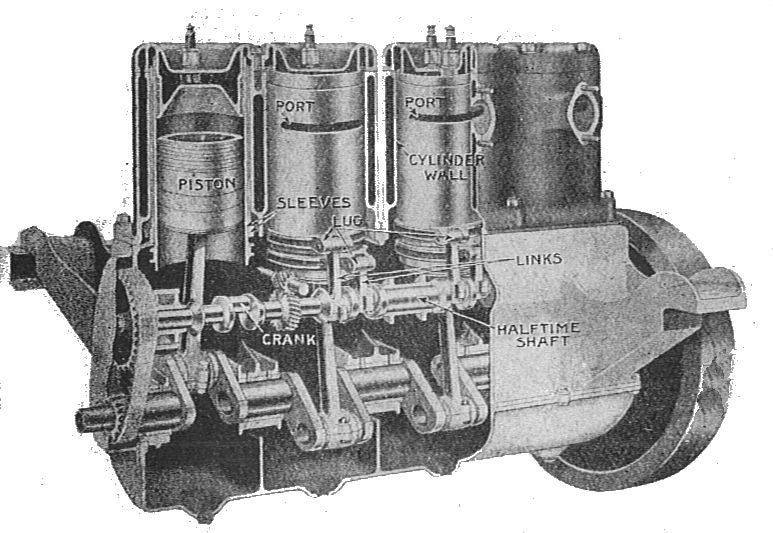

Early internal combustion engines, like the Otto cycle engine in the video above, used slide valves to control intake and exhaust gases, steam engine technology basically. Slide valves worked fine in steam engines, but were not ideally suited for internal combustion use, which is why poppet valves were tried next (although again, they had already been tried on steam engines in the 1770s). Poppet valves are ideal then right? We still use them today so they must be awesome! No actually, theyíre totally fucking awful, and really the weakest part of most any reciprocating engine ever made. Engineers collectively have probably wasted more time worrying about poppet valves and their related bullshit than theyíve spent on any other part of engine design.

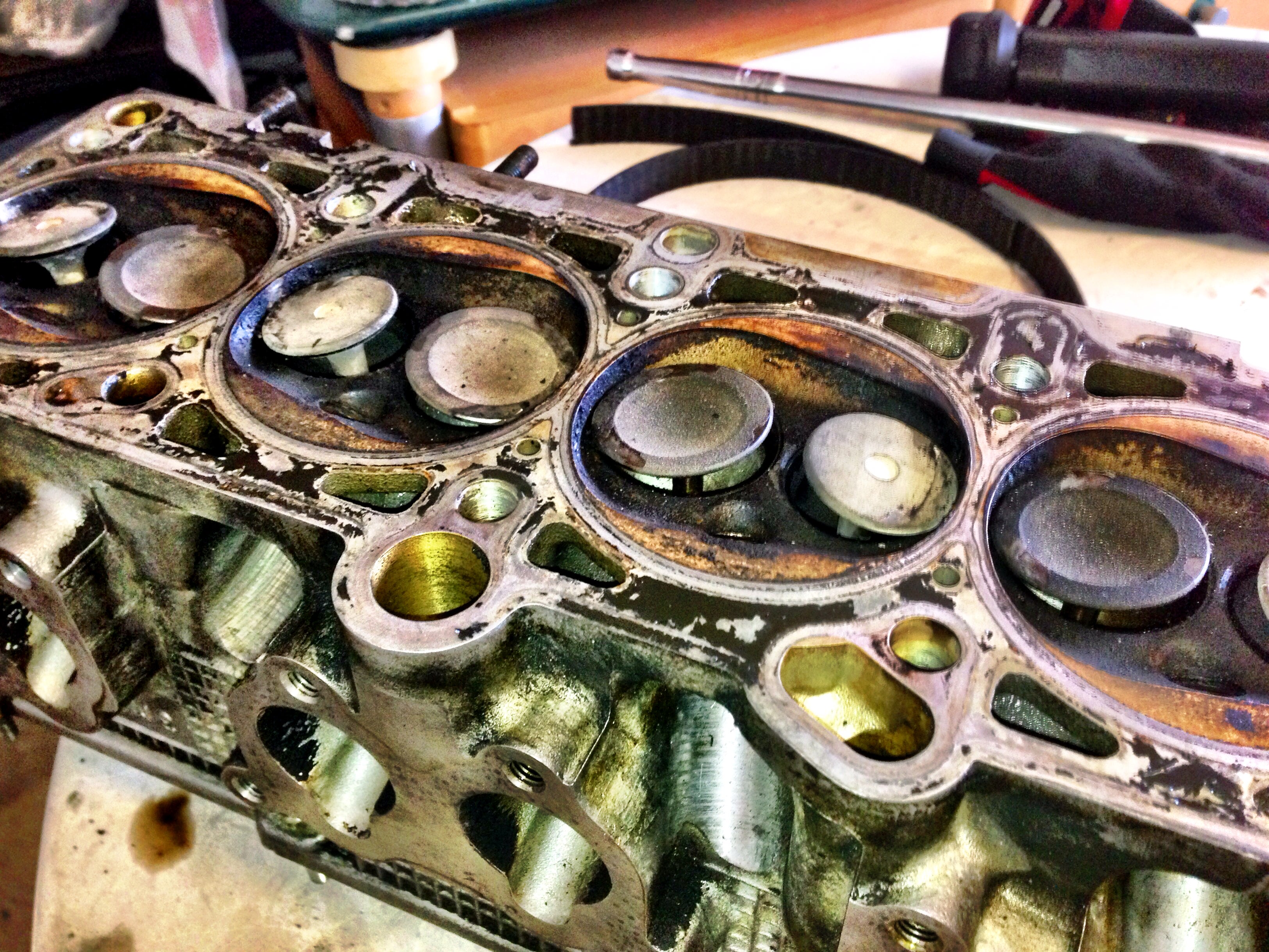

To understand why engineers were so keen to find something to replace poppet valves, one has to understand how inconvenient and awful poppet valves were (and to a large extent, still are). The first major problem is that a combustion chamber must be engineered to fit the valves. Which means that most combustion chambers, up until relatively recently, were not designed with efficient combustion in mind. They were designed to

fit valves

, with mechanical simplicity and economy of construction in mind - perfected burning of the intake charge took a backseat. In the early days keeping valves working was also a constant headache (but to be fair, so was every other aspect of keeping a car in tune). Adjusting, grinding, and replacing valves regularly was just a normal part of car maintenance. Luckily for the whole planet, it was discovered that dissolving lead into gasoline to be burned in poppet valve engines meant less valve maintenance! Hooray for that brilliant idea.

The whole valve train itself was also basically an engineering nightmare. Gears or chains? Belts? Pushrods? Rockers? Desmodromic actuation? Interference? How do we even get these things to open and close reliably? You want it simple and quiet? Youíd have an easier time brokering lasting world peace. Engineers were willing to try anything. Sleeve valves? Rotary valves? Whole rotary

engines

? Anything would be better, it seemed.

So itís easy to see why sleeve valves were a serious contender for a while. Sleeve valve engines ran quieter, smoother, and stronger. The lack of poppet valves meant a combustion chamber shaped more like what engineers thought a combustion chamber should be shaped like, and the higher compression ratios possible meant more power. The intake and exhaust ports could be larger than was possible with poppet valves, which also meant more power. But sleeve valves were expensive to produce, they had to be made to exacting dimensions, and poppet valves could be produced cheaply and slopped together by comparison. So sleeve valve engines were only fitted to more expensive cars - and to airplanes. The miracle of leaded gas and rising octane ratings eroded some of the benefits of sleeve valves, and after only a couple decades they disappeared from production automobiles (although they lived on in aviation use for a while longer). But long story short, engineers had seen the light. Poppet valves were nasty, awful things, and had to be made better or thrown away altogether.

Advances were made. Overhead cams allowed better combustion chamber shapes. Sodium filled valves didnít burn away. Hardened valve seats meant one didnít have to lap their valves every year - and better yet, meant leaded gas was no longer being burnt and then exhausted into the atmosphere, poisoning everything everywhere. Hydraulic lifters meant quieter engines and less maintenance (although I guess they werenít worth the cost, since weíve now mostly returned to solid lifters). Hey - at least the stupid things worked reliably after almost a century of engineering progress and tinkering.

What about making them perform well? Valve float? Better try a really strong, energy wasting spring. Or this complicated, but beautiful desmodromic actuation, which pulls and pushes the valves up and down (hey, kind of like a sleeve valve). In sum, poppet valves are totally shitty, medieval things, that generations of engineers have fashioned into something that works ok. Works ok, but is still an engineering nightmare. And you thought apex seals were tricky.

Do I still have space to talk about all the other reciprocating tech rooted in the dark ages or steam engines, like the cranks, con rods, balance shafts, and other parts? I think I might give it a rest for tonight. But bringing it back to the top - the reason the reciprocating internal combustion engine sucks, is that the whole thing is basically a bodge job. Itís just a steam engine with the fire moved inside the cylinder. Itís been and continues to be a lot of good engineering wasted on making a bad concept work well.

Demon-Xanth knows how to operate a street.

> Berang

Demon-Xanth knows how to operate a street.

> Berang

04/26/2016 at 20:04 |

|

VTEC in '86....1886.

yitznewton

> Demon-Xanth knows how to operate a street.

yitznewton

> Demon-Xanth knows how to operate a street.

04/26/2016 at 20:24 |

|

Just kicked in, yo

jimz

> Berang

jimz

> Berang

04/26/2016 at 20:25 |

|

youíre trying too hard.

Berang

> jimz

Berang

> jimz

04/26/2016 at 20:27 |

|

Thanks for the input. Iíll go back to not writing things on blogs, if it pleases your majesty.

this is not matt farah's foxbodymiata

> Berang

this is not matt farah's foxbodymiata

> Berang

04/26/2016 at 20:32 |

|

Shots fired!

RallyWrench

> Demon-Xanth knows how to operate a street.

RallyWrench

> Demon-Xanth knows how to operate a street.

04/26/2016 at 20:34 |

|

In a Mini; let them mock me as My Mini Countryman is higher than you

> Berang

In a Mini; let them mock me as My Mini Countryman is higher than you

> Berang

04/26/2016 at 20:37 |

|

>Implying that electric motors arent more complicated with voltage actuators

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Berang

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Berang

04/26/2016 at 20:37 |

|

Electric motors are the answer, if the battery tech could get closer to gasolineís energy density.

Berang

> In a Mini; let them mock me as My Mini Countryman is higher than you

Berang

> In a Mini; let them mock me as My Mini Countryman is higher than you

04/26/2016 at 20:43 |

|

I think more to the point, this would be to electrical motors what the reciprocating engine is to internal combustion engines. Now imagine if most of the electric motors in our life were solenoid motors.

jimz

> Berang

jimz

> Berang

04/26/2016 at 20:55 |

|

it pleases the court.

dsigned001 - O.R.C. hunter

> Berang

dsigned001 - O.R.C. hunter

> Berang

04/26/2016 at 21:55 |

|

Maybe you prefer an axial turbine?

I personally think little mini nuclear reactors is still a cool idea. Little 200kW reactor. Fuel up once a year, maybe once every ten years...

gogmorgo - rowing gears in a Grand Cherokee

> Berang

gogmorgo - rowing gears in a Grand Cherokee

> Berang

04/26/2016 at 23:03 |

|

The reason we continue to use the reciprocating engine is because weíve got it figured out to the point itís cheap, easy to use and implement, and both reliable and effective. Energy supplies are readily available and quick to recharge. Electric motors do not have quick energy recharge times. Turbine engines arenít cheap. Wankel rotaries arenít hugely reliable. Reciprocating motors may not be ideal, but frankly there's nothing out there that will do the same job as well or as cheaply. If it's stupid but it works, it's not stupid.

Berang

> gogmorgo - rowing gears in a Grand Cherokee

Berang

> gogmorgo - rowing gears in a Grand Cherokee

04/26/2016 at 23:36 |

|

Well there are things out there that will do the job as well. Just not as cheaply. But letís be honest here, the reciprocating piston engine is an antique, it only still works because companies wonít give up spending lots of time and money making it work no matter what. Thereís no point beating around the bush about that.

You can tell a Finn but you can't tell him much

> Berang

You can tell a Finn but you can't tell him much

> Berang

04/27/2016 at 13:23 |

|

They work because even with their low thermodynamic efficiency, the energy density of gasoline and diesel allow for long range and rapid refueling. The only way to generate enough energy to move a vehicle is by generating heat. The most efficient method for generating heat in a portable size is the internal combustion engine, and the most efficient and reliable engine that will fit in a car is the piston engine.

Berang

> You can tell a Finn but you can't tell him much

Berang

> You can tell a Finn but you can't tell him much

04/27/2016 at 13:29 |

|

Not 100% true, but close enough. Though none of that changes anything Iíve said in the post.